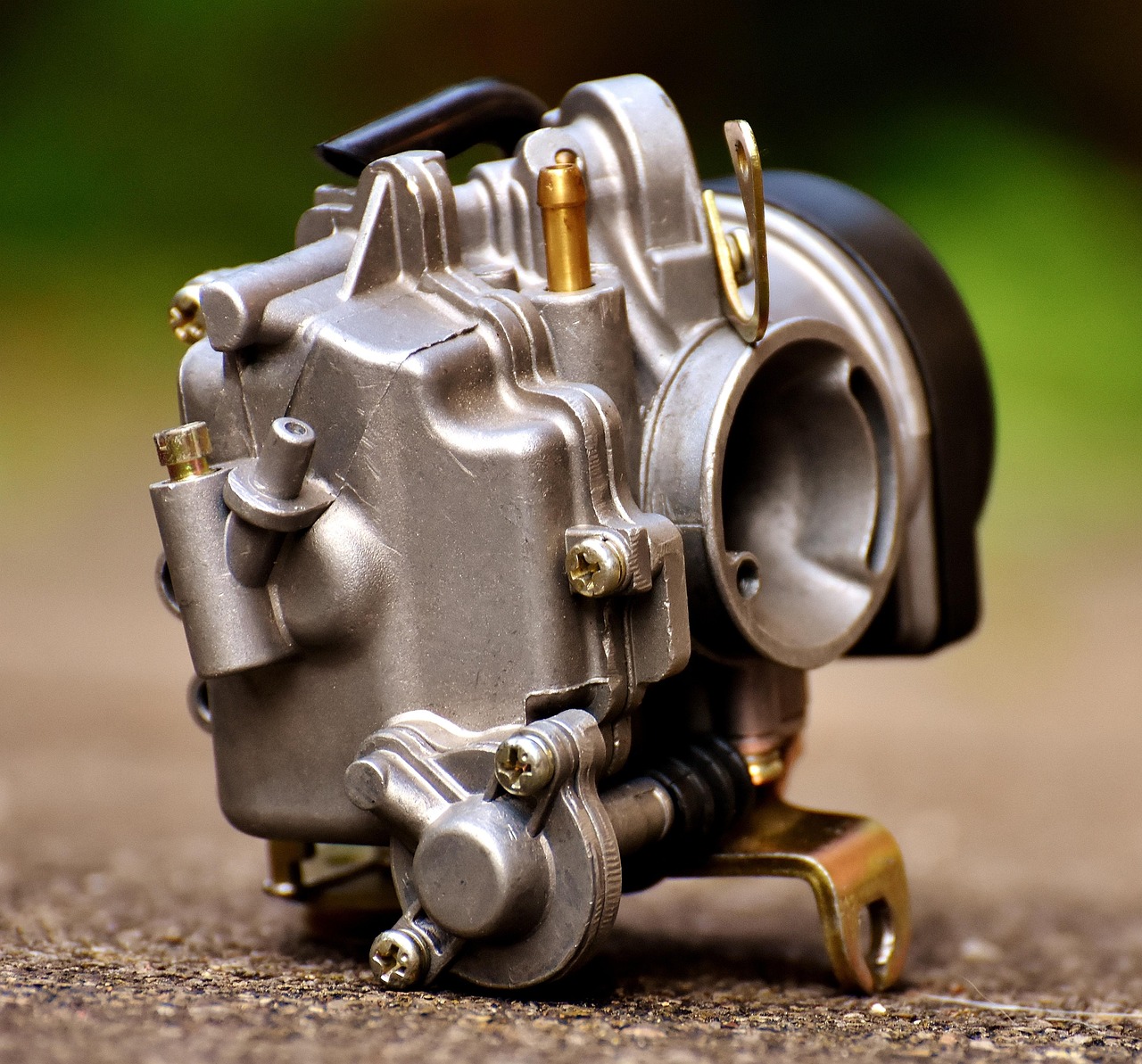

When it comes to restoring classic cars, motorbikes or scooters, one component that almost always requires attention is the carburettor. As the heart of the fuel system in many vintage vehicles, the carburettor is essential for proper performance—but over time, it can become clogged with old fuel residues, carbon deposits, corrosion, and grime.

Thorough cleaning is critical during any restoration, but due to its intricate internal passages and delicate materials, the carburettor demands a careful, expert approach.

Why Carburettors Need Specialist Cleaning

Vintage carburettors often contain a mix of aluminium, brass, and steel—all of which react differently to cleaning methods. Harsh blasting or abrasive media can damage sealing surfaces, distort tiny jets, or strip away valuable coatings. Even vigorous manual scrubbing may fail to reach the narrow internal channels where fuel and air flow.

That’s why it’s important to select the right cleaning method for the job—something that varies depending on the material, the condition of the part, and the type of contamination present.

Choosing the Right Media: Vapour Blasting, Laser Cleaning or Traditional Media Blasting

- Vapour blasting is an excellent choice for aluminium-bodied carburettors. It gently removes oxidation and grime while preserving surface integrity and maintaining a smooth, satin finish. The water and fine media combination helps clean even the most awkward recesses without causing damage.

- Laser cleaning is ideal for more sensitive or valuable carburettor components, particularly when precision is required and abrasive methods are too risky. It removes rust and deposits without making contact, helping to protect intricate features and fine details.

- Traditional media blasting has its place too, on harder-wearing steel components or external parts that require a coarser surface prep for paint adhesion. However, using the wrong media—or the wrong pressure—can do more harm than good.

Why Expert Advice Is Essential

At Bang On Blasters in Market Harborough, we tailor each cleaning job based on the part’s material, age, and function. Our experience means we know when vapour blasting is ideal, when laser cleaning is safer, and when to avoid abrasive blasting altogether.

Restoration is never one-size-fits-all. Using the wrong technique can compromise not just the part, but the entire rebuild. By consulting an experienced professional, you ensure your carburettor—and every component—gets the treatment it needs to function and look as good as new.